2025.03.04

Sustainability

Research and Development

Exploring a New Highly Durable Emulsion Primer For Construction Applications

In construction applications, self-leveling (SL) materials are important for creating smooth, level surfaces — particularly in flooring applications. These materials are often used in conjunction with emulsion primers, which prepare the substrate by enhancing adhesion and ensuring a uniform surface for the SL compound.

Yet despite their widespread use, emulsion primers face several challenges that can affect their performance and overall success of construction projects. One issue is ensuring adequate adhesion between the SL material and substrate. Emulsion primers also often contain volatile organic compounds (VOC), which pose health risks to workers and the environment.

A Sustainable Alternative With Strong Adhesion

Overcoming these challenges is Nippon Shokubai’s PX-2-PR-1 Series of highly durable emulsion primers. Designed for SL materials in harsh environments, including hot and cold temperatures, this emulsion primer offers an ideal adhesion film regardless of the conditions of the substrate. Whereas typical primers in SL materials often result in cracking, pinholes and other imperfections, PR-1 helps create an enduring, high-quality and long-lasting surface appearance.

Below is a comparison of PR-1 with other types of emulsion primers, including ethylene vinyl acetate (EVA), acrylic and epoxy, which requires the use of a cross-linking agent:

| PR-1 | EVA | Acrylic | Epoxy | |

|---|---|---|---|---|

| Adhesion | Very Good | Fair | Good | Excellent |

| Usability | Good (one component) | Good (one component) | Good (one component) | Poor (two components) |

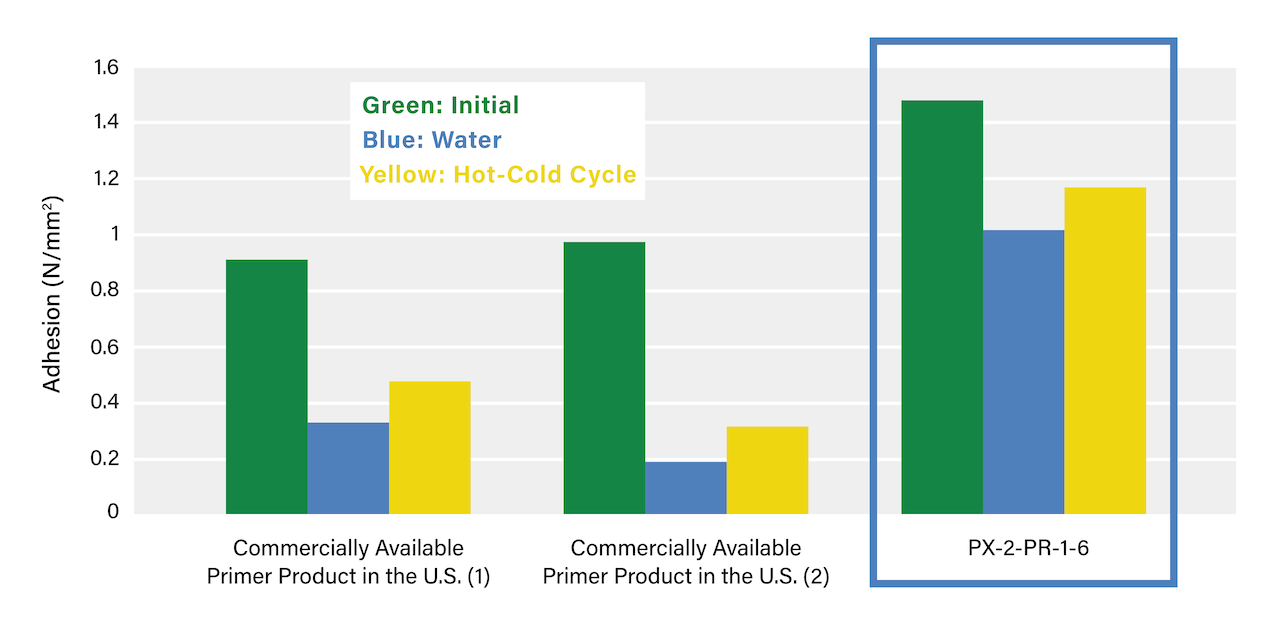

Tests using a mortar plate substrate indicate PX-2-PR-1-6 offered superior adhesion compared to other commercially available products in North America:

Initial tests (green) involved two-week curing in a thermo-hygrostat (20°C, 50%). In-water tests (blue) involved one-week curing in water after one-week curing in thermo-hygrostat (20°C, 50%). Hot-cold tests (yellow) involved five cycles of 18-hour curing in 20°C water, three-hour curing in a -20°C tank and three-hour curing in a 50°C tank. These cycles were performed after one week of curing in the thermo-hygrostat (20°C, 50%).

In addition to its high performance, PR-1 offers a more sustainable choice compared to other commonly used emulsion primers. It is free of VOCs and reduces the need for frequent flooring repairs.

Superior Salt Resistance

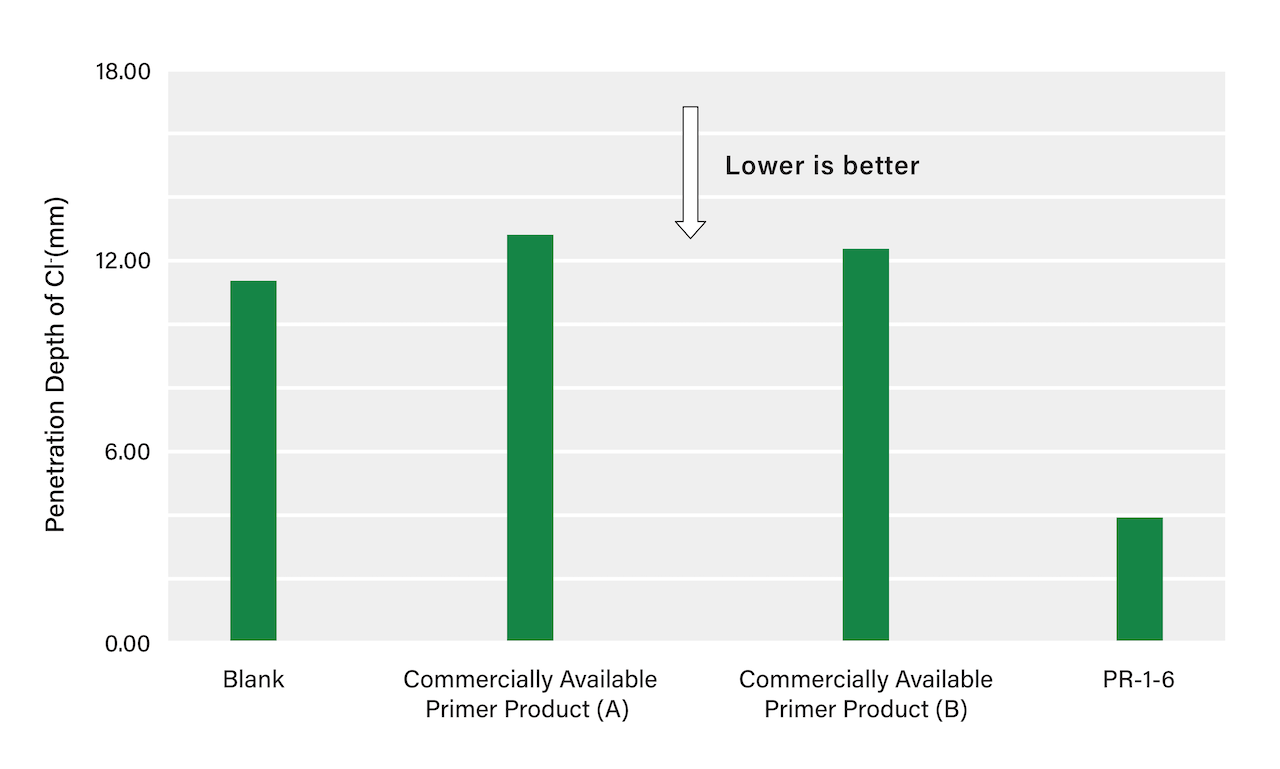

To evaluate the salt resistance of PR-1, we conducted a simple test involving the use of a color reagent — silver nitrate (AgNO3) aqueous solution — to visualize chloride ion penetration. The depth of chloride ion penetration was measured in millimeters (mm) for different samples.

We prepared mortar plates with primer and epoxy resin coatings, the latter of which would prevent additional penetration of chloride ions. Next, we immersed the plates in a sodium chloride (NaCl) solution to simulate saline conditions. Then, we split the plates and sprayed the internal surfaces with the silver nitrate solution. A color change to white indicated the presence of chloride ions. Finally, we measured the depth of chloride ion penetration for each sample.

The data indicates that PR-1 exhibits a significantly lower chloride ion penetration depth (4.0 mm) compared to the other samples, demonstrating its role as a highly effective primer for use in saline environments compared to other commercially available products:

Here’s a rundown of some of PR-1’s other characteristics:

- Offers water-borne emulsion with silicone modification technology.

- Water-proof and resistant to hot and cold temperatures.

- Accelerates the hydration reaction in cement.

- Solid content: 44.0-46.0%.

- pH: 7.0-9.0.

- Viscosity: 50-200 mPa·s.

- Eliminates the need to use a cross-linking agent.

To learn more about our PX-2-PR-1 Series, please contact us.

Newsletter Sign-Up

Sign up for our e-newsletter and learn more about what we do at NAII Page Top

Page Top  Back to List

Back to List